- Nur online erhältlich

Shell Rapid Lubricants Analysis is an oil condition monitoring service that helps you to keep your vessels running smoothly by identifying potential oil or equipment failures before they become critical. Shell RLA will help your business to save money and time on maintenance caused by equipment failures. Please ask for Shell Marine Service authentification and set up for use at helios lubes.

Shell RLA is not available for insulation oil, not for fuel or Jet A1 analysis. Please ask at HLAS helios analysis for these analytics. HLAS logon available for customers. Shell RLA is for lubricants marine prefered. More and detailed analysis at HLAS www.oilanalysis.eu Shell Services are assigned to helios lubeoil for Superyachts, Ultra-Large Yachts and other special Marine "objects" and vessel refits www.superyachtlube.eu

It is an early-warning system that aims to give you the peace of mind that your equipment and lubricants are in optimum working order.

Ask for analysis kit and sample bottles. Shell RLA Lab sent in address avaialable.

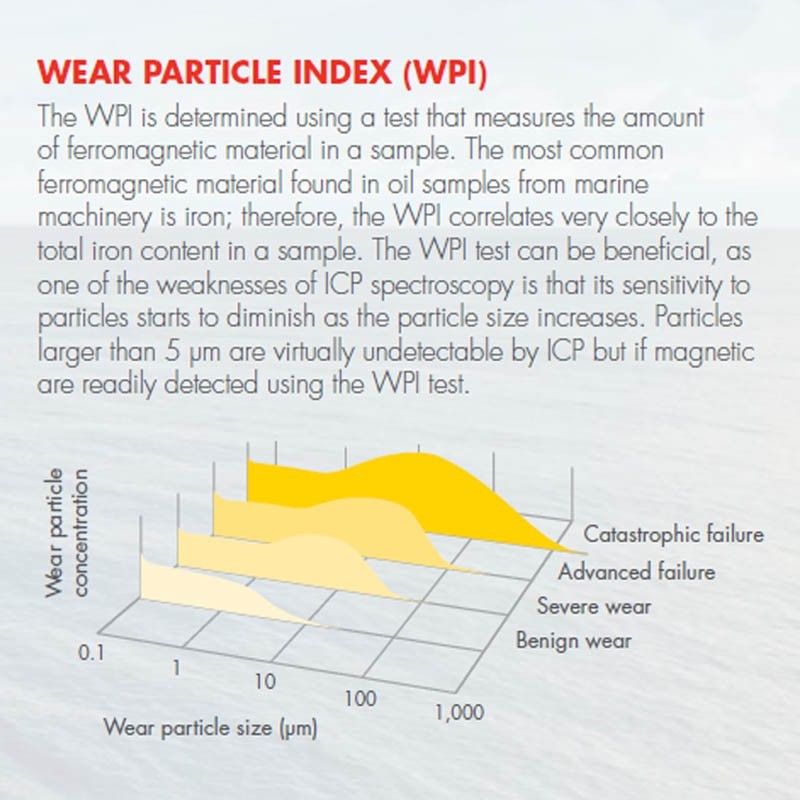

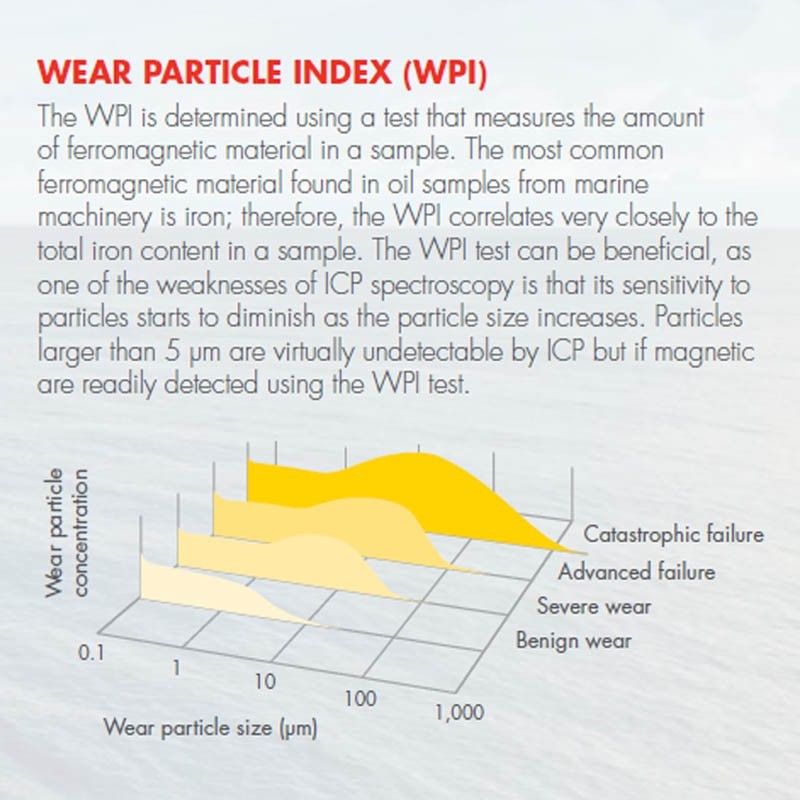

Used-oil analysis is a key tool in managing preventive and predictive maintenance. Many leading shipping companies use Shell RLA as an important part of their planned and predictive maintenance strategies to help deliver

Analysis shows that the return on investment can be up to 14 times the cost of the service.