- please sent email

Flame retardant hydraulic fluid and turbine lubricating oil. Shell Turbo Fluid DR 46 is a flame-retardant hydraulic and lubricating oil based on tri-aryl phosphates. Lubrication of Steam and Gas Turbines Shell Turbo Fluid DR 46, now Shell Turbo S5 DR 46, can be used to lubricate the main bearings in steam and gas turbines, generators and coolant pumps.

Specifications, Approvals & Recommendations

· Shell Turbo S5 DR 46 is approved and/or exceeds the requirements of the major original equipment manufacturers such as General Electric (GE), Mitsubishi Hitachi Power Systems (MHPS), and Siemens, etc.

· Shell Turbo S5 DR 46 is approved by FM (Factory Mutual) Global against Standard 6930 for 'Less flammable hydraulic fluids'. It also meets the requirements of ISO Standard 12922 and ASTM 4293 for HFDR-type fire-resistant hydraulic fluids.

Typical Physical Characteristics (excerpt)

| Properties | Method | Shell Turbo S5 DR 46 |

| ISO Viscosity Grade | ISO 3448 | 46 |

| Density @200C kg/m3 | ISO 3675 | 1 150 |

| Flash Point (COC) 0C | ASTM D92 | 262 |

| Fire Point (COC) 0C | ASTM D92 | 354 |

| Pour Point 0C | ISO 3016 | - 24 |

Main Applications

· Hydraulic fluid

It can be used as the hydraulic fluid in electrohydraulic governor control (EHC) systems in steam and gas turbines.

· Lubrication of steam and gas turbines

Shell Turbo S5 DR 46 can also be used as the lubricating oil for main bearings in steam and gas turbines, generators and cooling pumps. As a precaution its compatibility with system components should be confirmed.

Compatibility & Miscibility

· Compatibility - Packing, seals and hoses

The following materials are recommended for use with Shell Turbo S5 DR 46: Butyl rubbers, Nylon, PTFE, VITON rubber (depending on operation temperature range).

· Compatibility - Paints

Attention must be paid to painted surfaces. Cured epoxy paints are regarded as resistant to Shell Turbo S5 DR 46.

Compatibility - Other fluids

Shell Turbo S5 DR can be mixed in any proportion with other phosphate ester fluids. However, when combining different phosphate ester products, it is always suggested to monitor the performance of the system. The mixing of phosphate ester fluids with mineral oil and polyol esters, polyalkylene glycol and water-based fluids should be avoided. For more information, please consult your Shell Contact.

Performance, Features & Benefits

· Excellent fire resistance

Shell Turbo S5 DR 46 is a high-performance phosphate ester self-extinguishing fire-resistant fluid, offering high flash point, high fire point and high auto ignition temperature. It minimises the risk of fire, which could potentially be caused by mineral oil products.

· Good oxidation stability

To provide long service life under normal operating conditions.

· Good hydrolytic stability

Shell Turbo S5 DR 46 is to a great extent able to withstand rapid decomposition of the base fluid under the influence of moisture and water in the oil system.

· Good demulsibility

To enable rapid separation from water for improved service intervals.

· Controlled air release

Good air-release minimises air entrainment in lubrication and governor control systems in order to ensure safe operation of the whole equipment.

· Low foaming

Minimal tendency for foaming to provide proper lubrication and heat transfer.

· HSSE

Shell Turbo S5 DR 46 is an advanced low toxicity fireresistant hydraulic fluid that is trixylenyl phosphate (TXP)- free and is designed specifically to comply with future EU

REACH regulations for use in EHC systems. It is a fully formulated fluid based on tert-butylphenylphosphate.

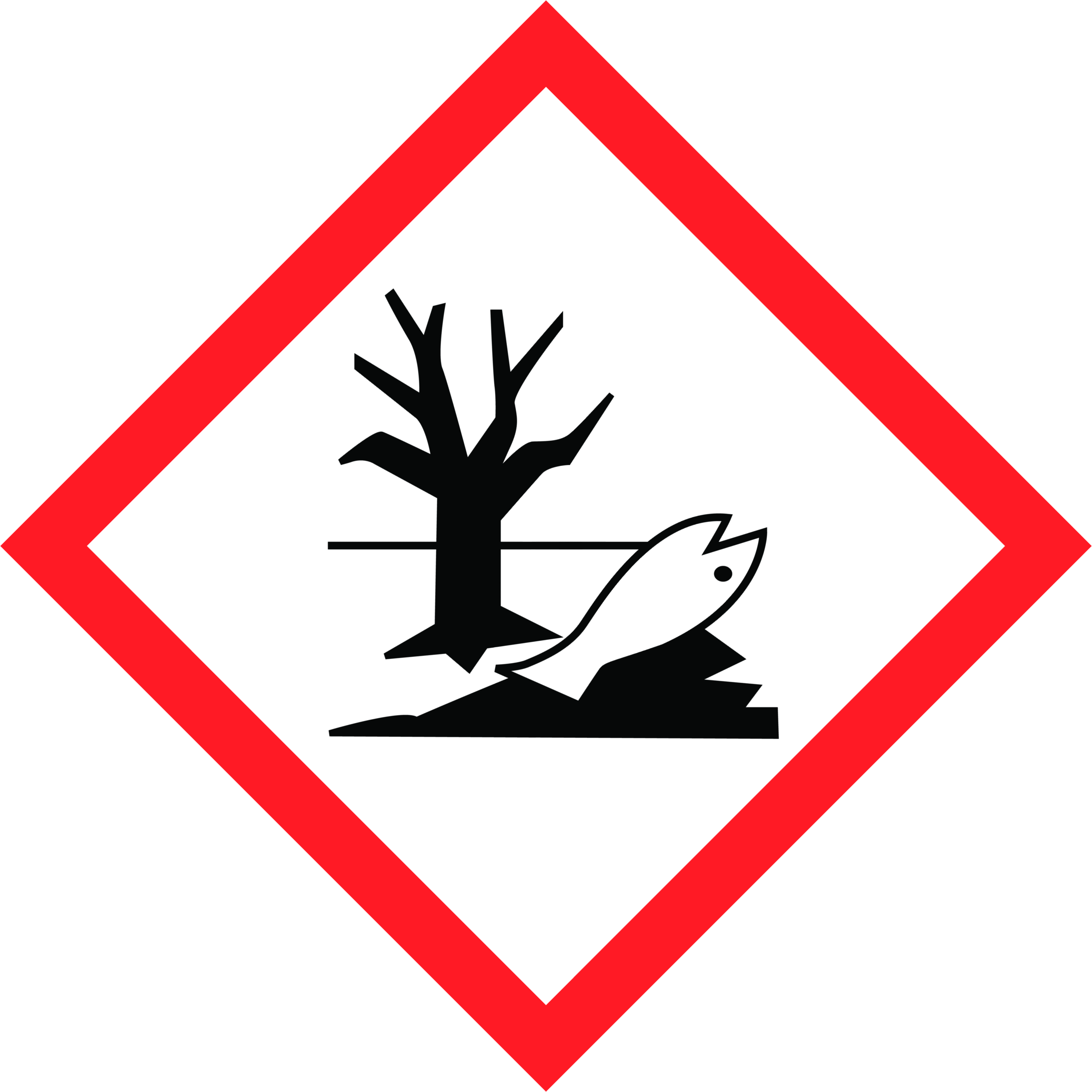

ADR dangerous goods 3082 ENVIRONMENTALLY HAZARDOUS SUBSTANCE, LIQUID, N.O.S. (Phenol, isobutylenated, phosphate [Triphenyl phosphate ≥ 0.25 ≤25%]) 04-2020 MSDS - ask for latest MSDS before shipping

|

Hazard statements : PHYSICAL HAZARDS: Not classified as a physical hazard according to CLP criteria. HEALTH HAZARDS: Not classified as a health hazard under CLP criteria. ENVIRONMENTAL HAZARDS: H411 Toxic to aquatic life with long lasting effects. |