Metalworking fluids

Metalworking oils, cutting oils, slideway oils, hardness fluids, GTL KSS, honing fluids, die oils, punching drawing oils, deep hole drilling oils, stainless steel composite cooling lubricants, multi-purpose automatic oils, grinding oils, forming oils, circulating oils, spindle oils, heat treatment fluids, corrosion protection fluids, cleaners and more are diverse Metalworking and composites - lightweight construction used. Houghton, QuakerHoughton

Competence + specialist knowledge lived in partnership with large manufacturers for general applications up to very special processing operations, taking into account various ordinances and regulations, delivered and made available to customers.

Subcategories

-

Metalworking oils

Metal working operations, and consists of many different materials.

Various metalworking fluids are mostly evaporation and fog. For some operations, the lubricants must evaporate or burn tei. They meet in a variety of viscosities your use eg: for grinding, honing, machining, stamping, flushing, cooling, broaching, deep drilling, tapping, cutting, hobbing, profile cutting, creep feed and profile cutting, shaping, drawing, rolling, pipe bending, tempering, and many further applications. For ferrous metals and nonferrous metals, ferrous metals, aluminum alloys, stainless steels, titanium, etc.NEW NEW NEW: synthetic cutting oils GTL base oil. Successful since 01-2015 in use

-

Anti Corrosion Fluids

Corrosion protection has been designed to, inside or outside, to ensure the short or long-term protection for surfaces of the metals. This protection is needed so that moisture, water, salt and other substances stay away. The workpiece or tool can be handled and transported. There are dewatering fluids for short-term operation interruption available.

The additional use of AntiCorr powder is contemporary. It is blown and infiltrated with its monomolecular structure moist and watery places. When working necessary it is not necessary to remove the corrosion protection. After processing, "grows the machining point to", thanks to the monomolecular structure of AntiCorr.

-

Water Miscible Coolant...

KSS water-miscible concentrate, CNC machine cooling, CNC greases, KSS high pressure fluids, Lathe milling,

Various water-miscible cooling lubricants are used. The products we use are free of chlorine, boron, nitrite and amines! The latest products are also free of formaldehyde. Active and continuously developed for decades. TRGS 611, VDI 3035 and BGR 143 are a matter of course.

- Very good wetting and flushing behavior

- Clean machines - less residue build-up

- Very little lime soap formation

- No filter clogging or blocking

- Good anti-corrosion properties

- Lower concentrations can be achieved

- Economical due to lower drag-out losses

- Good biostability generates longer service lives

- Good machine cleanliness and good dirt-carrying capacity, especially when machining castings.

- Both boron-free and boron-containing products are available

- Alternative formulations to prevent bacterial and fungal resistance

-

Heat Treatment

Hardening, annealing, quenching, tempering, process monitoring, quenching monitoring

Competence analyzes with first-class laboratory equipment up to a scanning electron microscope for assessing sections in heat treatment. Aim less consumption, resource-saving, clean, avoidance of water in the production aisles. Hardening, annealing, tempering and tempering.

Competence analysis, process monitoring, deterrent monitoring, cooling lubricant monitoring. Set the budget position for bath changes in good time through accompanying sampling and analysis. Oils don't last forever. Key words acid increase, scale entry, water entry, etc. In the ZTU, note that some cooling must be carried out in order to minimize the workpiece distortion. -

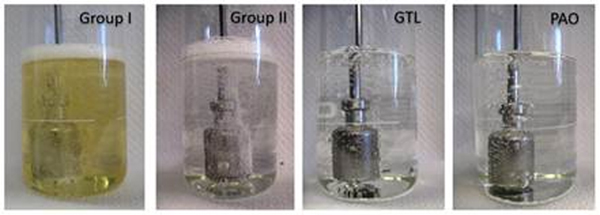

GTL synthetic cutting...

GTL cutting oil concentrate, Cut Max Houghton, GTL multi-purpose oil machining, GTL grinding fluid, GTL Scheid deep hole drilling oils, GTL gear manufacturing, profile + generating grinding, GTL broaching oils,

GTL cutting oils are mineral oil free. GTL cooling lubricants are environmentally friendly (EAL) base fluids that minimize CO2. Developed by Houghton for the machining industry. GTL synthetic cooling lubricants.

- Better health protection thanks to the very low proportion of aromatic hydrocarbons

- A high flash point is fire protection in industry

- Improved air quality in the workplace through low evaporation. More cleanliness and less risk of slipping in the hall.

- Improved lubrication at high temperature on the tool cutting edge.

- Less consumption due to less evaporation. More economical compared to other synthetic base oils.

- High UV and aging stability for a long bath life.

- A low pour point reduces the risk of frost damage to the fresh oil.

- Energy efficient due to low pump load

- Cutting oil for the turned parts industry

- Multipurpose oil for the machining of non-ferrous metals, gray cast iron and steel

- High-performance cutting, grinding and deep drilling oil with good high pressure properties.

- Grinding and cutting oil for gear manufacturing, profile and generating grinding

- High-alloy cutting and deep drilling oil, used e.g. in the manufacture of common rail injection nozzles and pumps

- Cutting and broaching oil for demanding machining in the field of automotive components

- Heaviest machining such as broaching racks for steering systems or workpieces made of nickel or titanium alloys

-

Cleaner Degreaser

Water-based process cleaners, after-treatment Glavanik Härti, rust removal, corrosion protection cleaners, system cleaners,

With water-based process cleaners additional productivity and profit maximization by helping to reduce rework and energy consumption.

Cleaners and degreasers are tailored to the post-treatment, electroplating, hardening shop and other surface-specific requirements of the reprocessing systems and previous rust removal. Dipping, flooding and spraying are the common methods for cleaning and corrosion protection, system cleaners, acidic or solvent-based cleaners depending on the individual processing in the overall process.