- please sent email

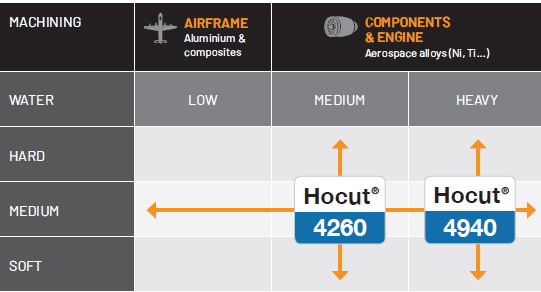

Hocut 4260 is an advanced, high lubricity metal removal fluid specially formulated for machining of a wide range of materials including aerospace aluminum alloys, high-alloy steels, stainless steel, composite materials and titanium.

This product holds the following approvals and conformities:

• Rolls Royce CSS129/131 approval

• Boeing BAC 5008 cat. 5 & 6 – Meets conformance requirements

• Bombardier BAMS 569-001: A, C & D. ASTM D 3946 and Storage stability – Meets conformance requirements

• Dassault - Approved

• Airbus AIMS 12-10-001 - Table A7.1 Cleaning tests, 80T-30-4010 - ASTM F483 and 80T-30-4010 - ASTM F1110 - Complies with requirements

• SNECMA - PR 6300 - Hot corrosion with Aluminium, nickel and titanium aluminium steels – Meets conformance requirements

WATER SOLUBLE METAL-WORKING FLUID

HOCUT 4260 is an advanced, boron-free and formaldehydefree emulsion technology giving very long sump-life. A special lubricity additive package gives greatly enhanced

machining performance and extends tool life compared to conventional products. HOCUT 4260 is particularly effective on machining aerospace airframe structural components in aluminium alloys including titanium and carbon-fibre composites.

APPLICATION

• HOCUT 4260 is multi-metal compatible and is recommended for a range of machining applications, including high speed milling and turning on a wide range of materials including aerospace aluminium alloys, composites, ferrous alloys, titanium and inconel.

• The product is suitable for both centralised systems and single sump machines while the advanced boron-free technology extends emulsion life without the need for regular biocide treatments.

• The versatile formulation is designed to give low foam and no soaps in soft to hard water (10°dH - 70 °dH cumulated hardness).

• Its operator-friendly EHS profile and its non-staining & corrosion-free properties make HOCUT

• Developed as a new product for Aerospace and general machining applications, especially for large aluminium parts or fuselage

• It is also compatible with titanium and carbon-fibre composites

• Anticipates future EHS regulations (exempt of Formaldehyde, Biocide, 2nd Amines…)

• Specifically developed to prevent staining and galvanic corrosion of Al alloys, particularly on large parts with long machining cycles.

REACh compliant. Safety data sheets are available in accordance with Regulations (EC) No 1907/2006 Annex II and (EC) No 1272/2008

STORAGE

Please refer to section 7 of Safety Data Sheets for handling and storage information, including product shelf life. Product should be stored under cover in clean, dry conditions and protected from frost. Recommended storage temperature is usually between 5°C and 40°C unless otherwise specified. Use stock in delivery rotation.